|

|

|

What it shows:

A step down transformer can have a sufficient increase in current in the secondary to heat and melt iron.

How it works:

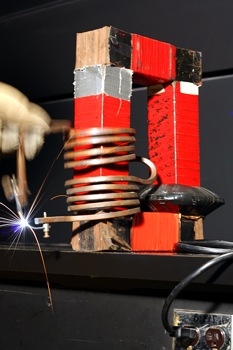

The primary is a 100 turn coil that is connected to the mains 110V supply. The secondary is a 9 turn coil made of 9 x 9mm iron. Attached to each end of the coil (their positions shown in Figure 1) are 2" nails. When the nail ends are brought together (by pressing the upper onto the lower) to complete the circuit in the secondary, the current is sufficient [+ how much?] to heat up and fuse the nail tips.

The transformer core cross section is 6 x 6cm made from layered iron strips, giving a total dimension of 36cm high and 24cm wide.

Figure 1. The welding transformer

Setting it up:

The nails can be pressed together by hand, but you may want to supply a glove to shield the sparks. Make sure that the top piece of the iron core of the transformer is in place before plugging in the 110V primary. Without it there is not enough inductance in the primary and the circuit breakers will trip.

Comments:

Very impressive display, with sparks and much loud humming!