Selection of blocks that slide down a variable-angle inclined plane to demonstrate the various aspects of friction.

What it shows:

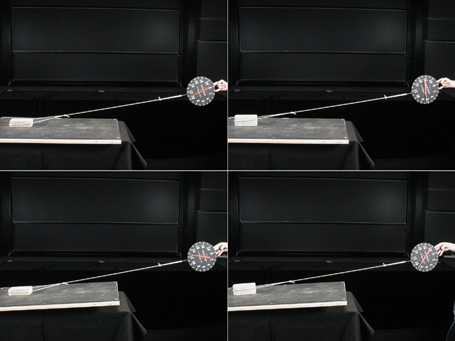

There are actually three (or more) demonstrations under the wing of this title: (1) A block or box is placed on an adjustable inclined plane which can be raised until the block slides. The tangent of the angle then gives the coefficient of friction between the surfaces. (2) The difference between dynamic and static friction may be demonstrated. A large dial spring balance is used to determine the forces required to drag a box on the floor. (3) Rectangular wooden blocks can be pulled across the lecture table with a dial scale. The block may be turned on different edges to show the independence of frictional forces on area. Similar blocks with various types of surfaces can be used to show the effects of different kinds of contact planes.

How it works:

As indicated above, these demonstrations are all variations on the same theme. We have large floor models, lecture bench-top versions, and the Klinger™ Blackboard Mechanics set to choose from. Choose the most appropriate for your needs, whether they be qualitative or quantitative or something else. Here is a quick overview.

(1) The adjustable inclined plane is a large wooden floor model measuring 240 cm long and 34 cm wide. It can be set at any angle between 0 and 21°. The surface is covered with Formica™ and is quite smooth. Large wood blocks or cardboard boxes (filled with stuff) can be used as the sliding objects.

(2-a) Here we typically use a very large (up to a meter3) cardboard box with one or two lead bricks placed on the bottom for weight. A 100 N dial spring-scale 1 is attached to the box via some rope and the box is dragged across the floor by pulling on the scale. The audience notes the different scale readings before and after the box begins to slide.

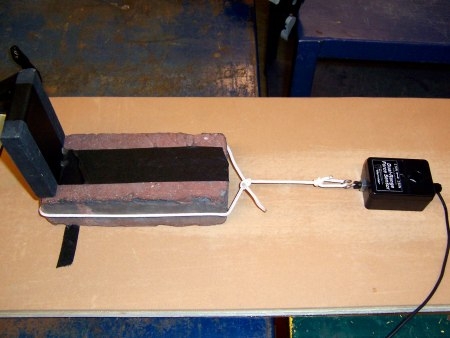

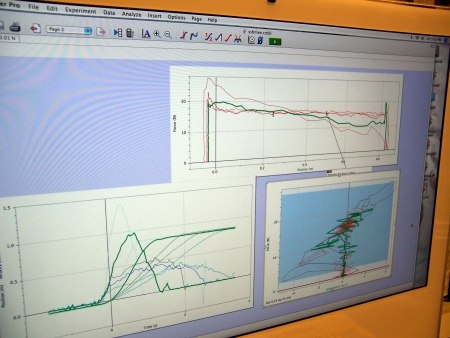

(2-b) A brick is pulled by a string, on the cork-surfaced adjustable inclined plane. The plane is used horizontally, clamped to a cart. It gives about a meter of cork surface, with a coefficient of friction of 0.6. The opposite end of the string is connected to a digital force sensor, which sends data to a computer running LoggerPro. A separate digital position sensor reflects sonar off of a small wood block taped to the brick. This records the position of the brick, so that LoggerPro can plot tension vs position as well as position vs time. This method can give more quantitative results than the spring-scale setup.

(3) On a smaller scale to (2) above, small wood blocks (around 10×10×30 cm) can be dragged on the Formica™-covered lecture bench-top using a 20 N scale. 2 Additionally, by flipping the block over onto one of its edges, one can demonstrate that the frictional force between two sliding surfaces is independent of the area of contact. Further, by stacking identical blocks on top of the sliding block, the spring-scale indicates that the frictional force is a function of the normal force applied by the sliding object to the plane surface. And finally, to demonstrate the dependence of the coefficient of friction (both static and dynamic) on the nature of the sliding surfaces, sandpaper and rubber have been glued onto some of the surfaces.

(4) If you wish to demonstrate "slip-n-stick" motion, spray Tuf-Skin® Tape Adherent (made by Cramer) on an acrylic surface and drag a block with smooth surfaces across it. Tuf-Skin® is rosin dissolved in isopropyl alcohol and its intended use is for athletics (to prevent tape and wraps from slipping). It works well for slip and stick motion.

Comments:

A bit of a drag.

1 Sargent-Welch cat. no. S-3775-30K

2 Sargent-Welch cat no. 4091